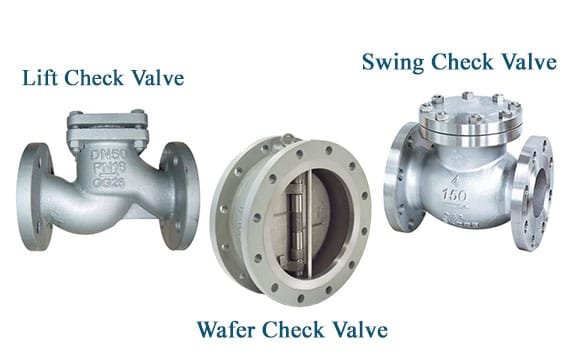

SWING CHECK VALVES

STANDARD SPECIFICATION

Production Range – 15 NB – 1000 NB

| API 603/ASME 16.34 | API 600/BS 1414 | ||

| Class | Size | Class | Size |

| 150 | 2” ~ 24” | 150 | 2” ~ 40” |

| 300 | 2” ~ 24” | 300 | 2” ~ 24” |

| 600 | 2” ~ 24” | 600 | 2” ~ 24” |

| 900 | 2” ~ 16” | ||

| 1500 | 2” ~ 12” | ||

| Pressure – Temperature Rating | ANSI B16.34 |

| Face to Face Dimensions | ANSI B16.10 |

| End Flange Dimensions | ASME B16.5 |

| Testing | API 598/ MSS-SP-41 |

| Bonnet Bolt | ASTM A193 |

| Bonnet Nut | ASTM A194 |

| Marking | MSS-SP-25 |

| Light Wall Thickness | API 603/ANSI B16.34 |

| Heavy Wall Thickness | API 600/BS 1868 |

| Part Name | Cast Steel Valves | Stainless Steel Valves | |||

| WCB | LCB | CF8M | CF8 | CF3M | |

| Body | A216-WCB | A352-LCB | A351-CF8M | A351-CF8 | A351-CF3M |

| Seat Ring | A105+CA15 | A182-F304 | Integral | ||

| Disc | A217-CA15 | A351-CF8 | A351-CF8M | A351-CF8 | A351-CF3M |

| Disc Nut | A194-8 | A194-8M | A194-8 | A479-316L | |

| Arm | A216-WCB | A352-LCB | A351-CF8M | A351-CF8 | A351-CF3M |

| Cover | A216-WCB | A352-LCB | A351-CF8M | A351-CF8 | A351-CF3M |

| Cover Bolt | A193-B7 | A320-L7 | A193-B8 | ||

| Cover Nut | A194-2H | A194-4 | A194-8 | ||

| Hinge Pin | A479-410 | A479-304 | A479-316 | A479-304 | A479-316L |

| Plug Bolt | A307-B | A194-8 | A193-B8M | A193-B8 | A479-316L |

| Plug Gasket | Soft Steel | 304SS | 304SS | ||

| Eye Bolt | A307-B | A193-B8 | |||

- We can supply any kind of Gasket and gland packing on request

- Stellite faced seat rings are available on request

SWING CHECK VALVES

DESIGN FEATURES

Body and Cover

The body is cast with uniform sections and generous radius fillets to prevent stress on all sides. The body is spherical in shape to prevent minimum turbulence, erosion and resistance to flow. The body-cover joint is male-female in ASME class 150-600 and ring type joint in class 900 and over. The cover material is identical to the body. The check valves are designed to give resistance against water hammer caused by a sudden reverse flow. Gasket materials can be supplied according to customer’s requirement.

Disc

The disc is constructed to have one piece to endure severe service conditions. It has a sufficient seating surface area which is ground and lapped to a mirror finish. The disc is of one-piece construction and is heat treated to deliver the required mechanical properties and hardness. It is securely fastened to the hinge by means of a lock nut with a cotter pin.

Seat Ring

The seat rings are designed to prevent any turbulence and damage by corrosion. They are forged or rolled in one piece and then seal welded and overlaid, if required. The forget seat ring is heat-treated to deliver the best mechanical properties and required hardness.

Arm

The disc stability is maintained while the disc is lifted by a hydrodynamic force at a flow including pulsating. The arm is designed to minimize water hammer because the disc goes to seat immediately upon cessation of flow due to heavy balanced weight.

Hinge

The hinge is designed to eliminate body penetration and allow ease of maintenance because all parts are accessible from the top. Body penetration is sealed with blind flange and spiral wound gasket. The hinge pin is located near the disc center of gravity resulting in minimizing sealing surface radius rotation and velocity.

End Connections

The standard flange ends have a raised face serrated finish type which conforms to ASME B16.5 RF. ASME class 600 valves are supplied with RTJ end flanges on request.

SWING CHECK VALVES

BOLTED BONNET SWING CHECK VALVES BASIC CONFIGURATON THREADED AND SOCKET WELD ENDS| WORKING PRESSURE RATING | SIZE | STANDARD DESIGN TYPE | A | B | H | WEIGHT | FIGURE | ||||||

| NPS | DN | mm | in | mm | in | mm | in | kg | lb | ||||

| ASME 800 | ½” | 15 | SI | 80 | 3.15 | 9.6 | 0.4 | 55 | 2.17 | 1.3 | 2.9 | HL 603 | STANDARD BORE |

| ¾” | 20 | SI | 90 | 3.54 | 14 | 0.6 | 60 | 2.36 | 1.6 | 3.5 | HL 604 | ||

| 1” | 25 | SI | 110 | 4.33 | 18 | 0.7 | 78 | 3.07 | 2.8 | 6.2 | HL 605 | ||

| 1-1/2” | 40 | SI | 150 | 5.91 | 30 | 1.2 | 92 | 3.62 | 5.6 | 12.3 | HL 607 | ||

| 2” | 50 | SI | 180 | 7.09 | 36.6 | 1.4 | 108 | 4.25 | 9 | 19.8 | HL 608 | ||

| ASME 1500 | ½” | 15 | SI | 90 | 3.54 | 9.6 | 0.4 | 60 | 2.36 | 1.7 | 3.7 | 9HL 603 | |

| ¾” | 20 | SI | 110 | 4.33 | 14 | 0.6 | 78 | 3.07 | 3 | 6.6 | 9HL 604 | ||

| 1” | 25 | SI | 127 | 5.00 | 18 | 0.7 | 88 | 3.46 | 4.4 | 9.7 | 9HL 605 | ||

| 1-1/2” | 40 | SI | 180 | 7.09 | 30 | 1.2 | 108 | 4.25 | 10 | 22.0 | 9HL 607 | ||

| 2” | 50 | SI | 210 | 8.27 | 36.6 | 1.4 | 145 | 5.71 | 18 | 39.7 | 9HL 608 | ||

| ASME 800 | ¼” | 6 | SI | 80 | 3.15 | 8 | 0.3 | 55 | 2.17 | 1.4 | 3.1 | H 601 | FULL BORE |

| 3/8” | 10 | SI | 80 | 3.15 | 9.6 | 0.4 | 55 | 2.17 | 1.4 | 3.1 | H 602 | ||

| ½” | 15 | SI | 90 | 3.54 | 14 | 0.6 | 60 | 2.36 | 1.6 | 3.5 | H 603 | ||

| ¾” | 20 | SI | 110 | 4.33 | 18 | 0.7 | 78 | 3.07 | 3 | 6.6 | H 604 | ||

| 1” | 25 | SI | 127 | 5.00 | 24 | 0.9 | 88 | 3.46 | 4.3 | 9.5 | H 605 | ||

| 1-1/4” | 32 | SI | 150 | 5.91 | 30 | 1.2 | 92 | 3.62 | 5.6 | 12.3 | H 606 | ||

| 1-1/2” | 40 | SI | 180 | 7.09 | 36.6 | 1.4 | 108 | 4.25 | 10 | 22.0 | H 607 | ||

| 2” | 50 | SI | 210 | 8.27 | 48 | 1.9 | 145 | 5.71 | 16 | 35.3 | H 608 | ||

| ASME 1500 | ½” | 15 | SI | 110 | 4.33 | 14 | 0.6 | 78 | 3.07 | 3.1 | 6.8 | 9H 603 | |

| ¾” | 20 | SI | 127 | 5.00 | 18 | 0.7 | 88 | 3.46 | 4.6 | 10.1 | 9H 604 | ||

| 1” | 25 | SI | 150 | 5.91 | 24 | 0.9 | 92 | 3.62 | 6.5 | 14.3 | 9H 605 | ||

| 1-1/4” | 32 | SI | 180 | 7.09 | 30 | 1.2 | 108 | 4.25 | 10.6 | 23.4 | 9H 606 | ||

| 1-1/2” | 40 | SI | 210 | 8.27 | 36.6 | 1.4 | 145 | 5.71 | 19 | 41.9 | 9H 607 | ||

| 2” | 50 | SI | 210 | 8.27 | 48 | 1.9 | 150 | 5.91 | 19 | 41.9 | 9H 608 | ||

| ASME 2500 | ½” | 15 | S2 | 150 | 5.91 | 11.5 | 0.5 | 128 | 5.04 | 7.5 | 16.5 | 25HR 603 | |

| ¾” | 20 | S2 | 150 | 5.91 | 15 | 0.6 | 128 | 5.04 | 7.5 | 16.5 | 25HR 604 | ||

| 1” | 25 | S2 | 210 | 8.27 | 19.5 | 0.8 | 152 | 5.98 | 18.5 | 40.8 | 25HR 605 | ||

| 1-1/2” | 40 | S2 | 230 | 9.06 | 28 | 1.1 | 190 | 7.48 | 30 | 66.1 | 25HR 607 | ||

| 2” | 50 | S2 | 230 | 9.06 | 35 | 1.4 | 190 | 7.48 | 30 | 66.1 | 25HR 608 | ||

- Internal Pin Design.

SWING CHECK VALVES

BOLTED BONNET SWING CHECK VALVES

BASIC CONFIGURATION

ASME INTEGRAL FLANGED ENDS

| WORKING PRESSURE RATING | SIZE | STANDARD DESIGN TYPE | A-RF | A-RJ | B | WEIGHT | FIGURE | |||||||||||

| NPS | DN | mm | in | mm | in | mm | in | mm | in | kg | lb | |||||||

| ASME 150 | ½” | 15 | SI | 108 | 4.25 | N.A. | N.A. | 9.6 | 0.38 | 75 | 3.0 | 2.2 | 4.9 | L1-603 | STANDARD BORE | |||

| ¾” | 20 | SI | 117.5 | 4.63 | N.A. | N.A. | 14 | 0.55 | 75 | 3.0 | 3.1 | 6.8 | L1-604 | |||||

| 1” | 25 | SI | 127 | 5.00 | 140 | 5.51 | 17.5 | 0.69 | 85 | 3.3 | 4.4 | 9.7 | L1-605 | |||||

| 1-1/2” | 40 | SI | 165 | 6.50 | 178 | 7.01 | 29.5 | 1.16 | 110 | 4.3 | 8.3 | 18.3 | L1-607 | |||||

| 2” | 50 | SI | 203 | 7.99 | 216 | 8.50 | 36.6 | 1.44 | 125 | 4.9 | 13 | 28.7 | L1-608 | |||||

| ASME 300 | ½” | 15 | SI | 152.5 | 6.00 | 163.5 | N.A. | 9.6 | 0.38 | 75 | 3.0 | 3.3 | 7.3 | L3-603 | ||||

| ¾” | 20 | SI | 178 | 7.01 | 178 | 7.01 | 14 | 0.55 | 80 | 3.1 | 5.2 | 11.5 | L3-604 | |||||

| 1” | 25 | SI | 216 | 8.50 | 216 | 8.50 | 17.5 | 0.69 | 88 | 3.5 | 7.4 | 16.3 | L3-605 | |||||

| 1-1/2” | 40 | SI | 241 | 9.49 | 254 | 10.00 | 29.5 | 1.16 | 115 | 4.5 | 13.5 | 29.8 | L3-607 | |||||

| 2” | 50 | SI | 267 | 10.51 | 283 | 11.14 | 36.6 | 1.44 | 130 | 5.1 | 19 | 41.9 | L3-608 | |||||

| ASME 600 | ½” | 15 | SI | 165 | 6.50 | 163 | 6.42 | 9.6 | 0.38 | 72 | 2.8 | 3.5 | 7.7 | L6-603 | ||||

| ¾” | 20 | SI | 191 | 7.52 | 191 | 7.52 | 14 | 0.55 | 80 | 3.1 | 5.7 | 12.6 | L6-604 | |||||

| 1” | 25 | SI | 216 | 8.50 | 216 | 8.50 | 17.5 | 0.69 | 85 | 3.3 | 8 | 17.6 | L6-605 | |||||

| 1-1/2” | 40 | SI | 241 | 9.49 | 241 | 9.49 | 29.5 | 1.16 | 115 | 4.5 | 14.5 | 32.0 | L6-607 | |||||

| 2” | 50 | SI | 292 | 11.50 | 295 | 11.61 | 36.6 | 1.44 | 130 | 5.1 | 19.5 | 43.0 | L6-608 | |||||

| ASME 150 | ½” | 15 | SI | 108 | 4.25 | N.A. | N.A. | 14 | 0.55 | 75 | 3.0 | 2.8 | 6.2 | 1-603 | ||||

| ¾” | 20 | SI | 117 | 4.61 | N.A. | N.A. | 18 | 0.71 | 85 | 3.3 | 3.6 | 7.9 | 1-604 | |||||

| 1” | 25 | SI | 127 | 5.00 | 140 | 5.51 | 24 | 0.94 | 100 | 3.9 | 5.2 | 11.5 | 1-605 | |||||

| 1-1/2” | 40 | SI | 165 | 6.50 | 178 | 7.01 | 36.6 | 1.44 | 125 | 4.9 | 10 | 22.0 | 1-607 | |||||

| 2” | 50 | SI | 203 | 7.99 | 216 | 8.50 | 48 | 1.89 | 140 | 5.5 | 16 | 35.3 | 1-608 | FULL BOR E | ||||

| ASME 300 | ½” | 15 | SI | 152.5 | 6.00 | N.A. | N.A | 14 | 0.55 | 75 | 3.0 | 3.6 | 7.9 | 3-603 | ||||

| ¾” | 20 | S1 | 178 | N.A. | 178 | N.A. | 18 | 0.71 | 90 | 3.5 | 6.4 | 14.1 | 3-604 | |||||

| 1” | 25 | S1 | 216 | 8.50 | 229 | 9.02 | 24 | 0.94 | 100 | 3.9 | 8.2 | 18.1 | 3-605 | |||||

| 1-1/2” | 40 | S1 | 241 | 9.49 | 2.54 | 10.00 | 36.6 | 1.44 | 120 | 4.7 | 15 | 33.1 | 3-607 | |||||

| 2” | 50 | S1 | 267 | 10.51 | 283 | 11.14 | 48 | 1.89 | 150 | 5.9 | 21 | 46.3 | 3-608 | |||||

| ASME 600 | ½” | 15 | SI | 165 | 6.50 | 163 | 6.42 | 14 | 0.55 | 75 | 3.0 | 3.8 | 8.4 | 6-603 | ||||

| ¾” | 20 | SI | 191 | 7.52 | 191 | 7.52 | 18 | 0.71 | 90 | 3.5 | 6.5 | 14.3 | 6-604 | |||||

| 1” | 25 | SI | 216 | 8.50 | 216 | 8.50 | 24 | 0.94 | 100 | 3.9 | 8.5 | 18.7 | 6-605 | |||||

| 1-1/2” | 40 | SI | 241 | 9.49 | 241 | 9.49 | 36.6 | 1.44 | 120 | 4.7 | 16 | 35.3 | 6-607 | |||||

| 2” | 50 | SI | 292 | 11.50 | 295 | 11.61 | 48 | 1.89 | 150 | 5.9 | 23 | 50.7 | 6-608 | |||||

| ASME 1500 | ½” | 15 | SI | 216 | 8.50 | 216 | 8.50 | 14 | 0.55 | 105 | 4.1 | 7.5 | 16.5 | 15F 603 | ||||

| ¾” | 20 | SI | 229 | 9.02 | 229 | 9.02 | 18 | 0.71 | 125 | 4.9 | 11.2 | 24.7 | 15F 604 | |||||

| 1” | 25 | SI | 254 | 10.00 | 254 | 10.00 | 24 | 0.94 | 135 | 5.3 | 14.5 | 32.0 | 15F 605 | |||||

| 1-1/2” | 40 | SI | 305 | 12.01 | 305 | 12.01 | 36.6 | 1.44 | 155 | 6.1 | 26.5 | 58.4 | 15F 607 | |||||

| 2” | 50 | SI | 368 | 14.49 | 371 | 14.61 | 48 | 1.89 | 195 | 7.7 | 50 | 110.2 | 15F 608 | |||||

| ASME 2500 | ½” | 15 | SI | 264 | 10.39 | 264 | 10.39 | 11.5 | 0.45 | 128 | 5.0 | 14.3 | 31.5 | 25RF 603 | ||||

| ¾” | 20 | SI | 273 | 10.75 | 273 | 10.75 | 15 | 0.59 | 130 | 5.1 | 16 | 35.3 | 25RF 604 | |||||

| 1” | 25 | SI | 308 | 12.13 | 308 | 12.13 | 19.5 | 0.77 | 152 | 6.0 | 26.3 | 58.0 | 25RF 605 | |||||

| 1-1/2” | 40 | SI | 384 | 15.12 | 387 | 15.24 | 28 | 1.10 | 188 | 7.4 | 54 | 119.0 | 25RF 607 | |||||

| 2” | 50 | SI | 451 | 17.76 | 454 | 17.87 | 35 | 1.38 | 190 | 7.5 | 56 | 123.5 | 25RF 608 | |||||

- Internal Pin Design.

- Integral body flanges.

ASME CLASS 150

DIMENSIONS

Cast steel & Stainless Steel Swing Check Valve: Bolted cover, Swing type disc.

Size | FACE TO FACE | API 603 (RF ENDS) | API 603 (RF ENDS) | ||||||||

L1:RF | L2 : RTJ | L3:BW | H | H | |||||||

mm | inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | inch |

50 | 2 | 203 | 216 | 8-1/2 | 203 | 8 | 153 | 6 | 5-3/7 | ||

65 | 2-1/2 | 216 | 229 | 9 | 216 | 8-1/2 | 155 | 6-1/9 | 155 | 6-1/9 | |

80 | 3 | 241 | 9-1/2 | 254 | 10 | 241 | 9-1/2 | 175 | 6-8/9 | 160 | 6-2/7 |

100 | 4 | 292 | 11-1/2 | 305 | 12 | 292 | 11-1/2 | 202 | 8 | 201 | 8 |

150 | 6 | 356 | 16 | 368 | 14-1/2 | 406 | 16 | 291 | 11-1/2 | 248 | 9-3/4 |

200 | 8 | 495 | 19-1/2 | 508 | 20 | 495 | 19-1/2 | 327 | 12-7/8 | 293 | 11-1/2 |

250 | 10 | 622 | 24-1/2 | 635 | 25 | 622 | 24-1/2 | 360 | 14-1/6 | 300 | 13 |

300 | 12 | 699 | 27-1/2 | 711 | 28 | 698 | 27-1/2 | 417 | 16-3/7 | 354 | 14 |

350 | 14 | 787 | 31 | 800 | 31-1/2 | 787 | 31 | 478 | 18-5/6 | 387 | 15-1/4 |

400 | 16 | 864 | 36 | 876 | 34-1/2 | 914 | 36 | 516 | 20-1/3 | 421 | 16-4/7 |

450 | 18 | 978 | 38-1/2 | 991 | 39 | 978 | 38-1/2 | 554 | 21-4/5 | 461 | 16-1/7 |

500 | 20 | 978 | 38-1/2 | 991 | 39 | 978 | 38-1/2 | 620 | 24-2/5 | 526 | 20-5/7 |

600 | 24 | 1295 | 51 | 1308 | 51-1/2 | 1295 | 51 | 670 | 26-3/8 | 568 | 22-1/3 |

ASME CLASS 300

DIMENSIONS

Cast Steel & Stainless Steel Swing Check Valve:

Bolted cover, Swing type disc.

Size | FACE TO FACE | API 600 (RF ENDS) | API 603 (RF ENDS) | ||||||||

L1:RF | L2 : RTJ | L3:BW | H | H | |||||||

mm | inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | inch |

50 | 2 | 267 | 10-1/2 | 283 | 11-1/8 | 267 | 10-1/2 | 165 | 6-1/2 | 152 | 6 |

65 | 2-1/2 | 292 | 11-1/2 | 308 | 12-1/8 | 292 | 11-1/2 | 190 | 7-1/2 | 164 | 6-1/2 |

80 | 3 | 318 | 12-1/2 | 333 | 13-1/8 | 318 | 12-1/2 | 186 | 7-1/3 | 176 | 7 |

100 | 4 | 356 | 14 | 372 | 14-5/8 | 356 | 14 | 219 | 8-5/8 | 1856 | 73 |

150 | 6 | 444 | 17-1/2 | 460 | 18-1/8 | 444 | 17-1/2 | 262 | 10-1/3 | 262 | 10-1/3 |

200 | 8 | 533 | 21 | 549 | 21-5/8 | 533 | 21 | 334 | 13-1/7 | 312 | 12-2/7 |

250 | 10 | 622 | 24-1/2 | 638 | 25-1/8 | 622 | 24-1/2 | 398 | 15-2/3 | 355 | 14 |

300 | 12 | 711 | 28 | 727 | 28-5/8 | 711 | 28 | 475 | 18-5/7 | 393 | 15-1/2 |

350 | 14 | 838 | 33 | 854 | 33-5/8 | 838 | 33 | 540 | 21-1/4 | 440 | 17-1/3 |

400 | 16 | 864 | 34 | 880 | 34-5/8 | 864 | 34 | 605 | 23-5/6 | 480 | 18-8/9 |

450 | 18 | 978 | 38-1/2 | 994 | 39-1/8 | 978 | 38-1/2 | 650 | 25-3/5 | 535 | 21 |

500 | 20 | 1016 | 40 | 1035 | 40-3/4 | 1016 | 40 | 715 | 28-1/7 | 575 | 22-2/3 |

600 | 24 | 1346 | 53 | 1368 | 53-7/8 | 1346 | 53 | 964 | |||

ASME CLASS 600

DIMENSIONS

Cast steel & Stainless Steel Swing Check Valve:

Bolted cover, Swing type disc.

Size | FACE TO FACE | API 600 (RF ENDS) | API 603 (RF ENDS) | ||||||||

L1:RF | L2 : RTJ | L3:BW | H | H | |||||||

mm | inch | mm | inch | mm | inch | mm | inch | mm | inch | mm | inch |

50 | 2 | 292 | 11-1/2 | 295 | 11-5/8 | 292 | 11-1/2 | 187 | 7-1/3 | 187 | 7-1/3 |

65 | 2-1/2 | 330 | 13 | 333 | 13-1/8 | 330 | 13 | 200 | 7-7/8 | 200 | 7-7/8 |

80 | 3 | 356 | 14 | 359 | 14-1/8 | 356 | 14 | 210 | 8-1/4 | 210 | 8-1/4 |

100 | 4 | 432 | 17 | 435 | 17-1/8 | 432 | 17 | 256 | 10 | 256 | 10 |

150 | 6 | 559 | 22 | 562 | 22-1/8 | 559 | 22 | 329 | 13 | 329 | 13 |

200 | 8 | 660 | 26 | 664 | 26-1/8 | 660 | 26 | 364 | 14-1/3 | 364 | 14-1/3 |

250 | 10 | 787 | 31 | 791 | 31-1/8 | 787 | 31 | 464 | 18-1/4 | 464 | 18-1/4 |

300 | 12 | 838 | 33 | 841 | 33-1/8 | 838 | 33 | 486 | 19-1/7 | 486 | 19-1/7 |

350 | 14 | 889 | 35 | 892 | 35-1/8 | 889 | 35 | 515 | 20-2/7 | 515 | 20-2/7 |

400 | 16 | 991 | 39 | 994 | 39-1/8 | 991 | 39 | 560 | 21-2/3 | 550 | 21-2/3 |

450 | 18 | 1092 | 43 | 1095 | 43-1/8 | 1092 | 43 | 590 | 23-2/9 | 590 | 23-2/9 |

500 | 20 | 1194 | 47 | 1200 | 47-1/4 | 1194 | 47 | 635 | 25 | 635 | 25 |

600 | 24 | 1397 | 55 | 1407 | 55-3/8 | 1397 | 55 | 680 | 26-7/9 | 680 | 26-7/9 |

ASME CLASS 900 & 1500

DIMENSIONS

Cast steel & Stainless Steel Check Valve:

Bolted cover, Swing type disc.

| Size | FACE TO FACE | API 600 (RF ENDS) | |||||||

| L1:RF | L2 : RTJ | L3:BW | H | ||||||

| mm | inch | mm | inch | mm | inch | mm | inch | mm | inch |

| Class 900 | |||||||||

| 50 | 2 | 368 | 14-1/2 | 372 | 14-5/8 | 368 | 14-1/2 | 270 | 10-5/8 |

| 80 | 3 | 381 | 15 | 384 | 15-1/8 | 381 | 15 | 295 | 11-3/5 |

| 100 | 4 | 457 | 18 | 460 | 18-1/8 | 457 | 18 | 310 | 12-1/5 |

| 150 | 6 | 610 | 24 | 613 | 24-1/8 | 610 | 24 | 340 | 13-2/5 |

| 200 | 8 | 737 | 29 | 740 | 29-1/8 | 737 | 29 | 465 | 18-1/3 |

| 250 | 10 | 838 | 33 | 841 | 33-1/8 | 838 | 33 | 510 | 20 |

| 300 | 12 | 965 | 38 | 968 | 38-1/8 | 965 | 38 | 580 | 22-5/6 |

| 350 | 14 | 1029 | 40-1/2 | 1038 | 40-7/8 | 1029 | 40-1/2 | 665 | 26-1/6 |

| 400 | 16 | 1130 | 44-1/2 | 1140 | 44-7/8 | 1130 | 44-1/2 | 750 | 29-1/2 |

| Class 1500 | |||||||||

| 50 | 2 | 368 | 14-1/2 | 372 | 14-5/8 | 368 | 14-1/2 | 290 | 11-3/7 |

| 80 | 3 | 470 | 18-1/2 | 473 | 18-5/8 | 470 | 18-1/2 | 315 | 12-2/5 |

| 100 | 4 | 545 | 21-1/2 | 549 | 21-5/8 | 545 | 21-1/2 | 380 | 15 |

| 150 | 6 | 706 | 27-3/4 | 711 | 28 | 706 | 27-3/4 | 490 | 19-2/7 |

| 200 | 8 | 832 | 32-3/4 | 841 | 33-1/8 | 832 | 32-3/4 | 600 | 23-5/8 |

| 250 | 10 | 900 | 39 | 1000 | 39-3/8 | 900 | 39 | 730 | 28-3/4 |

| 300 | 12 | 1130 | 44-1/2 | 1146 | 45-1/8 | 1130 | 44-1/2 | 850 | 33-1/2 |

PARTLIST AND STANDARD MATERIAL SPECIFICATION

MODEL FB1

| NO | Part Name | Q’ty | Carbon Steel | Stainless Steel |

| 1 | Body | 1 | A216-WCB | A351-CF8M |

| 2 | Retainer | 1 | A216-WCB | A351-CF8M |

| 3 | Ball | 1 | A351-CF8M | A351-CF8M |

| 4 | Stem | 1 | A276-316 | A276-316 |

| 5 | Gland | 1 | A276-304 | A276-304 |

| 6 | Gland Flange | 1 | A167-304 | A167-304 |

| 7 | Stopper | 1 | A167-304 | A167-304 |

| 8 | Handle | 1 | DUCTILE CAST IRON | |

| 9 | Thrust Washer | 1 | PTFE | PTFE |

| 10 | Gland packing | 1Set | Graphite+Carbon Fiber | Graphite +Carbon Fiber PTFE |

| 11 | Seat | 2 | Super Tetion | Super Tetion |

| 12 | Gasket | 1 | Graphite | Graphite |

| 13 | Gasket | 1 | PTFE | PTFE |

| 14 | Stem Bearing | 1Set | RTFE | RTFE |

| 15 | Handle Bolt | 1Set | A193-B8 | A193-B8 |

| 16 | Gland Bolt | 2 | A193-B7M | A193-B8M |

PART LIST AND STANDARD MATERIAL SPECIFICATIONS

MODEL FB2

No | Part Name | Q’ty | Carbon Steel | Stainless Steel |

1 | Body | 1 | A216-WCB | A351-CF8M |

2 | Retainer | 1 | A216-WCB | A351-CF8M |

3 | Ball | 1 | A351-CF8M | A351-CF8M |

4 | Stem | 1 | A276-316 | A276-316 |

5 | Gland | 1 | A276-304 | A276-304 |

6 | Gland Flange | 1 | A351-CF8 | A351-CF8 |

7 | Stopper | 1 | A167-304 | A167-304 |

8 | Handle | 1 | Ductile Cast Iron | |

9 | Thrust Washer | 1 | PTFE | PTFE |

10 | Gland packing | 1Set | Graphite+Carbon Fiber | Graphite+Carbon Fiber PTFE |

11 | Seat | 2 | Super Tetion | Super Tetion |

12 | Gasket | 1 | 316Hoop+Graphite | 316Hoop+Graphite |

13 | Stem Bearing | 1 | RTFE | RTFE |

14 | Cap Bolt | 1Set | A193-B7M | A193-B8M |

15 | Cap Bolt Nut | 1Set | A194-2HM | A194-8M |

16 | Gland Bolt | 2 | A193-B7M | A193-B8M |

17 | Handle Bolt | 1 | A193-B8 | A193-B8 |

PISTON & BALL CHECK VALVES

BOLTED BONNET PISTON & BALL CHECK VALVES

BASIC CONFIGURATION

THREADED AND SOCKET WELD ENDS

| WORKING PRESSURE RATING | SIZE | STANDARD DESIGN TYPE | A | B | H | WEIGHT | FIGURE PISTON CHECK | FIGURE BALL CHECK | |||||

| NPS | DN | mm | in | mm | in | mm | in | kg | lb | ||||

| ASME 800 | ½” | 15 | SI | 80 | 3.15 | 9 | 0.35 | 55 | 2.17 | 1.3 | 2.9 | HL 403 | HL 503 |

| ¾” | 20 | SI | 90 | 3.54 | 13 | 0.51 | 60 | 2.36 | 1.6 | 3.5 | HL 404 | HL 504 | |

| 1” | 25 | SI | 110 | 4.33 | 17 | 0.66 | 78 | 3.07 | 2.8 | 6.2 | HL 405 | HL 505 | |

| 1-1/2” | 40 | SI | 150 | 5.91 | 29 | 1.14 | 92 | 3.62 | 5.6 | 12.3 | HL 407 | HL 507 | |

| 2” | 50 | SI | 180 | 7.09 | 35 | 1.38 | 108 | 4.25 | 9 | 19.8 | HL 408 | HL 508 | |

| ASME 1500 | ½” | 15 | SI | 90 | 3.54 | 9 | 0.35 | 60 | 2.36 | 1.7 | 3.7 | 9HL 403 | 9HL 503 |

| ¾” | 20 | SI | 110 | 4.33 | 12 | 0.47 | 78 | 3.07 | 3 | 6.6 | 9HL 404 | 9HL 504 | |

| 1” | 25 | SI | 127 | 5.00 | 15 | 0.59 | 88 | 3.46 | 4.4 | 9.7 | 9HL 405 | 9HL 505 | |

| 1-1/2” | 40 | SI | 180 | 7.09 | 27 | 1.06 | 108 | 4.25 | 10 | 22.0 | 9HL 407 | 9HL 507 | |

| 2” | 50 | SI | 210 | 8.27 | 32 | 1.26 | 145 | 5.71 | 18 | 39.7 | 9HL 408 | 9HL 508 | |

| ASME 800 | ¼” | 6 | SI | 80 | 3.15 | 7 | 0.28 | 55 | 2.17 | 1.4 | 3.1 | H 401 | H 501 |

| 3/8” | 10 | SI | 80 | 3.15 | 9 | 0.35 | 55 | 2.17 | 1.4 | 3.1 | H 402 | H 502 | |

| ½” | 15 | SI | 90 | 3.54 | 13 | 0.51 | 60 | 2.36 | 1.6 | 3.5 | H 403 | H 503 | |

| ¾” | 20 | SI | 110 | 4.33 | 17 | 0.66 | 78 | 3.07 | 3 | 6.6 | H 404 | H 504 | |

| 1” | 25 | SI | 127 | 5.00 | 22 | 0.86 | 88 | 3.46 | 4.3 | 9.5 | H 405 | H 505 | |

| 1-1/4” | 32 | SI | 150 | 5.91 | 29 | 1.14 | 92 | 3.62 | 5.6 | 12.3 | H 406 | H 506 | |

| 1-1/2” | 40 | SI | 180 | 7.09 | 35 | 1.38 | 108 | 4.25 | 10 | 22.0 | H 407 | H 507 | |

| 2” | 50 | SI | 210 | 8.27 | 45 | 1.77 | 145 | 5.71 | 16 | 35.3 | H 408 | H 508 | |

| ASME 1500 | 1/4” | 6 | SI | 90 | 3.54 | 7 | 0.28 | 60 | 2.36 | 1.7 | 3.7 | 9H 401 | 9H 501 |

| 3/8” | 10 | SI | 90 | 3.54 | 9 | 0.35 | 60 | 2.36 | 1.7 | 3.7 | 9H 402 | 9H 502 | |

| ½” | 15 | SI | 110 | 4.33 | 12 | 0.47 | 78 | 3.07 | 3.1 | 6.8 | 9H 403 | 9H 503 | |

| 3/4” | 20 | SI | 127 | 5.00 | 15 | 0.59 | 88 | 3.46 | 4.6 | 10.1 | 9H 404 | 9H 504 | |

| 1” | 25 | SI | 150 | 5.91 | 20 | 0.79 | 92 | 3.62 | 6.5 | 14.3 | 9H 405 | 9H 505 | |

| 1-1/4” | 32 | SI | 180 | 7.09 | 27 | 1.06 | 108 | 4.25 | 10.6 | 23.4 | 9H 406 | 9H 506 | |

| 1-1/2” | 40 | SI | 210 | 8.27 | 32 | 1.26 | 145 | 5.71 | 19 | 41.9 | 9H 407 | 9H 507 | |

| 2” | 50 | SI | 210 | 8.27 | 38 | 1.50 | 150 | 5.91 | 19 | 41.9 | 9H 408 | 9H 508 | |

| ASME 2500 | ½” | 15 | S2 | 150 | 5.91 | 11 | 0.43 | 128 | 5.04 | 7.5 | 16.5 | 25HR 403 | 25HR 503 |

| ¾” | 20 | S2 | 150 | 5.91 | 14.5 | 0.57 | 128 | 5.04 | 7.5 | 16.5 | 25HR 404 | 25HR 504 | |

| 1” | 25 | S2 | 210 | 8.27 | 19 | 0.75 | 152 | 5.98 | 18.5 | 40.8 | 25HR 405 | 25HR 505 | |

| 1-1/2” | 40 | S2 | 230 | 9.06 | 28 | 1.10 | 190 | 7.48 | 30 | 66.1 | 25HR 407 | 25HR 507 | |

| 2” | 50 | S2 | 230 | 9.06 | 38 | 1.50 | 190 | 7.48 | 30 | 66.1 | 25HR 408 | 25HR 508 | |

- Body-Bonnet weld to ASME IX

PISTON & BALL CHECK VALVES

BOLTED BONNET PISTON & BALL CHECK VALVES

BASIC CONFIGURATION

ASME INTEGRAL FLANGED ENDS

| WORKING PRESSURE RATING | SIZE | STANDARD DESIGN TYPE | A-RF | A-RJ | B | H | WEIGHT | FIGURE PISTON CHECK | FIGURE BALL CHECK | ||||||||

| NPS | DN | mm | in | mm | in | mm | in | mm | in | kg | lb | ||||||

| ASME 150 | ½” | 15 | SI | 108 | 4.25 | N.A. | N.A. | 10 | 0.39 | 75 | 3.0 | 2.3 | 3.1 | L1-403 | L1-503 | ||

| ¾” | 20 | SI | 117.5 | 4.63 | N.A. | N.A. | 14 | 0.55 | 75 | 3.0 | 3.1 | 6.8 | L1-404 | L1-504 | |||

| 1” | 25 | SI | 127 | 5.00 | 140 | 5.51 | 17 | 0.66 | 85 | 3.3 | 4.5 | 9.9 | L1-405 | L1-505 | |||

| 1-1/2” | 40 | SI | 165 | 6.50 | 178 | 7.01 | 29 | 1.14 | 110 | 4.3 | 8.4 | 18.5 | L1-407 | L1-507 | |||

| 2” | 50 | SI | 203 | 7.99 | 216 | 8.50 | 35 | 1.38 | 125 | 4.9 | 14 | 30.9 | L1-408 | L1-508 | |||

| ASME 300 | ½” | 15 | SI | 152.5 | 6.00 | 163.6 | 6.44 | 9 | 0.35 | 75 | 3.0 | 3.4 | 7.5 | L3-403 | L3-503 | ||

| ¾” | 20 | SI | 178 | 7.01 | 190.5 | 7.50 | 13 | 0.51 | 80 | 3.1 | 5.3 | 11.7 | L3-404 | L3-504 | |||

| 1” | 25 | SI | 203 | 7.99 | 216 | 8.50 | 17 | 0.66 | 88 | 3.5 | 7.5 | 16.5 | L3-405 | L3-505 | |||

| 1-1/2” | 40 | SI | 229 | 9.02 | 241 | 9.49 | 29 | 1.14 | 115 | 4.5 | 14 | 30.9 | L3-407 | L3-507 | |||

| 2” | 50 | SI | 267 | 10.51 | 282.5 | 11.12 | 35 | 1.38 | 130 | 5.1 | 19 | 41.9 | L3-408 | L3-508 | |||

| ASME 600 | ½” | 15 | SI | 165 | 6.50 | 163.5 | 6.44 | 9 | 0.35 | 75 | 2.8 | 3.5 | 7.7 | L6-403 | L6-503 | ||

| ¾” | 20 | SI | 191 | 7.52 | 190.5 | 7.50 | 13 | 0.51 | 80 | 3.1 | 5.7 | 12.6 | L6-404 | L6-504 | |||

| 1” | 25 | SI | 216 | 8.50 | 216 | 8.50 | 17 | 0.66 | 85 | 3.3 | 8 | 17.6 | L6-405 | L6-505 | |||

| 1-1/2” | 40 | SI | 241 | 9.49 | 241 | 9.49 | 29 | 1.14 | 115 | 4.5 | 14.5 | 32.0 | L6-407 | L6-507 | |||

| 2” | 50 | SI | 292 | 11.50 | 295 | 11.61 | 35 | 1.38 | 130 | 5.1 | 19.5 | 43.0 | L6-408 | L6-508 | |||

| ASME 1500 | ½” | 15 | SI | 216 | 8.50 | 216 | 8.50 | 9 | 0.35 | 85 | 3.3 | 6.5 | 14.3 | 15FL 403 | 15FL 503 | ||

| ¾” | 20 | SI | 229 | 9.02 | 229 | 9.02 | 14 | 0.55 | 100 | 3.9 | 10.2 | 22.5 | 15FL 404 | 15FL 504 | |||

| 1” | 25 | SI | 254 | 10.00 | 254 | 10.00 | 14 | 0.55 | 105 | 4.1 | 13.5 | 29.8 | 15FL 405 | 15FL 505 | |||

| 1-1/2” | 40 | SI | 305 | 12.01 | 305 | 12.01 | 26 | 1.02 | 125 | 4.9 | 25.5 | 56.2 | 15FL 407 | 15FL 507 | |||

| 2” | 50 | SI | 368 | 14.49 | 371.5 | 14.63 | 34 | 1.34 | 165 | 6.5 | 49 | 108.0 | 15FL 408 | 15FL 508 | |||

| ASME 150 | ½” | 15 | SI | 108 | 4.25 | N.A. | N.A. | 13 | 0.51 | 75 | 3.0 | 2.8 | 6.2 | 1-403 | 1-503 | ||

| ¾” | 20 | S1 | 117.5 | 4.63 | N.A. | N.A. | 17.5 | 0.69 | 85 | 3.3 | 3.6 | 7.9 | 1-404 | 1-504 | |||

| 1” | 25 | S1 | 127 | 5.00 | 140 | 5.51 | 22.5 | 0.89 | 100 | 3.9 | 5.2 | 11.5 | 1-405 | 1-505 | |||

| 1-1/2” | 40 | S1 | 165 | 6.50 | 178 | 7.01 | 35 | 1.38 | 125 | 4.9 | 10 | 22.0 | 1-407 | 1-507 | |||

| 2” | 50 | S1 | 203 | 7.99 | 216 | 8.50 | 45 | 1.77 | 140 | 5.5 | 16 | 35.3 | 1-408 | 1-508 | |||

| ASME 300 | ½” | 15 | SI | 152.5 | 6.00 | 163.5 | 6.44 | 13 | 0.51 | 75 | 3.0 | 3.6 | 7.9 | 3-403 | 3-503 | ||

| ¾” | 20 | SI | 178 | 7.01 | 190.5 | 7.50 | 17.5 | 0.69 | 90 | 3.5 | 6.4 | 14.1 | 3-404 | 3-504 | |||

| 1” | 25 | SI | 203 | 7.99 | 216 | 8.50 | 22.5 | 0.89 | 100 | 3.9 | 8.2 | 18.1 | 3-405 | 3-505 | |||

| 1-1/2” | 40 | SI | 229 | 9.02 | 241 | 9.49 | 35 | 1.38 | 120 | 4.7 | 15 | 33.1 | 3-407 | 3-507 | |||

| 2” | 50 | SI | 267 | 10.51 | 282.51 | 11.12 | 45 | 1.77 | 150 | 5.9 | 21 | 46.3 | 3-408 | 3-508 | |||

| ASME 600 | ½” | 15 | SI | 165 | 6.50 | 163.5 | 6.44 | 13 | 0.51 | 75 | 3.0 | 3.8 | 8.4 | 6-403 | 6-503 | ||

| ¾” | 20 | SI | 191 | 7.52 | 190.5 | 7.50 | 17.5 | 0.69 | 90 | 3.5 | 6.5 | 14.3 | 6-404 | 6-504 | |||

| 1” | 25 | SI | 216 | 8.50 | 216 | 8.50 | 22.5 | 0.89 | 100 | 3.9 | 8.5 | 18.7 | 6-405 | 6-505 | |||

| 1-1/2” | 40 | SI | 241 | 9.49 | 241 | 9.49 | 35 | 1.38 | 120 | 4.7 | 16 | 35.3 | 6-407 | 6-507 | |||

| 2” | 50 | SI | 292 | 11.50 | 295 | 11.61 | 45 | 1.77 | 150 | 5.9 | 23 | 50.7 | 6-408 | 6-508 | |||

| ASME 1500 | ½” | 15 | SI | 216 | 8.50 | 216 | 8.50 | 12 | 0.47 | 99 | 3.9 | 6.5 | 14.3 | 15F 403 | 15F 503 | ||

| ¾” | 20 | SI | 229 | 9.02 | 229 | 9.02 | 14.5 | 0.57 | 119 | 4.7 | 10.2 | 22.5 | 15F 404 | 15F 504 | |||

| 1” | 25 | SI | 254 | 10.00 | 254 | 10.00 | 19 | 0.75 | 129 | 5.1 | 13.5 | 29.8 | 15F 405 | 15F 505 | |||

| 1-1/2” | 40 | SI | 305 | 12.01 | 305 | 12.01 | 31 | 1.22 | 149 | 5.9 | 25.5 | 56.2 | 15F 407 | 15F 507 | |||

| 2” | 50 | SI | 368 | 14.49 | 371.5 | 14.63 | 38 | 1.50 | 189 | 7.4 | 49 | 108.0 | 15F 408 | 15F 508 | |||

| ASME 2500 | ½” | 15 | S2 | 264 | 10.39 | 264 | 10.39 | 11 | 0.43 | 122 | 4.8 | 13.3 | 29.3 | 25RF 403 | 25RF 503 | ||

| ¾” | 20 | S2 | 273 | 10.75 | 273 | 10.75 | 14.5 | 0.57 | 124 | 4.9 | 15 | 33.1 | 25RF 404 | 25RF 504 | |||

| 1” | 25 | S2 | 308 | 12.13 | 308 | 12.13 | 19 | 0.75 | 146 | 5.7 | 25.3 | 55.8 | 25RF 405 | 25RF 505 | |||

| 1-1/2” | 40 | S2 | 384 | 15.12 | 387 | 15.24 | 28 | 1.10 | 182 | 7.2 | 53 | 116.8 | 25RF 407 | 25RF 507 | |||

| 2” | 50 | S2 | 451 | 17.76 | 454 | 17.87 | 35 | 1.38 | 184 | 7.2 | 55 | 121.3 | 25RF 408 | 25RF 508 | |||

- Outside Screw and Yoke (OS&Y).

- Self aligning two packing gland.

- Integral backseat.

- Integral body flanges.